How to choose the packaging manufacturer you need?

Foreword

- Is your product ready to hit the shelves?

- Are you still worried about the packaging of your products?

- How to choose among the numerous manufacturers in the market?

The Chinese say that “people need clothes, and Buddha needs gold clothes.” Any product without exception needs a suitable packaging to catch the attention of consumers. Packaging is not the main product, but it is a silent sales force that increases the value of the product virtually.

How to find a suitable packaging manufacturer?

Full qualification certificate. Complete commercial qualification certificates refer to the certificates, certificates and other formal qualifications obtained by enterprises or organizations to prove their professional knowledge, reputation and quality. They are their commitment to quality, safety and sustainability, and they are a stepping stone to formal cooperation. Packaging manufacturers have formal industry qualification certificates, indicating that industry organizations have done the first step of large-scale screening for enterprises and merchants, saving a lot of material and financial resources in searching for certificates on it. Cooperating with manufacturers with formal qualifications can minimize risks and seek protection for the packaging quality and safety of your products.

Types of qualifications that packaging manufacturers need to obtain:

- Enterprise legal person business license

- Environmental certificate

- Quality system certification: such as ISO9001, ISO14001 and other certificates that prove that the enterprise’s quality management, environmental management and other systems meet international standards.

- Product quality and safety certification certificates: such as CE certification, FDA certification, etc., which prove that the products produced by the enterprise meet national or international standards.

- Industrial and Commercial Bureau Trademark Registration Certificate

The above certificates are the qualification certificates required in most regions. The specific requirements may vary from region to region. If you need to know more about it, it is recommended to consult the relevant local institutions for details.

Guarantee production efficiency. Have you ever experienced the anxiety caused by the fact that the product is about to be put on the shelves and can be packaged but has not been produced? It is imperative to choose a manufacturer that can guarantee production efficiency if you don’t want to encounter such anxiety again. To ensure production efficiency, manufacturers must meet the following conditions:

Packaging production workshop: a dedicated production workshop is a prerequisite for packaging to ensure production efficiency;

Automated production process: There is a complete and mature automated production process, and production operations will not be delayed due to frequent accidents;

Optimizing the production process: Manufacturers that can guarantee quality and efficiency will not stop at the present, and will independently optimize the production process in stages to maximize production fluency and avoid production accidents;

Implement quality control measures: implement effective quality control measures in real time to ensure that each product meets quality standards, avoid invalid operations and high probability of rework, and save time and cost;

Use high-quality materials: Inferior materials will cause damage to the machine, will increase the frequency of failures and reduce the actual production time, eating high-quality materials can help reduce unnecessary waste and improve the overall efficiency of the production process.

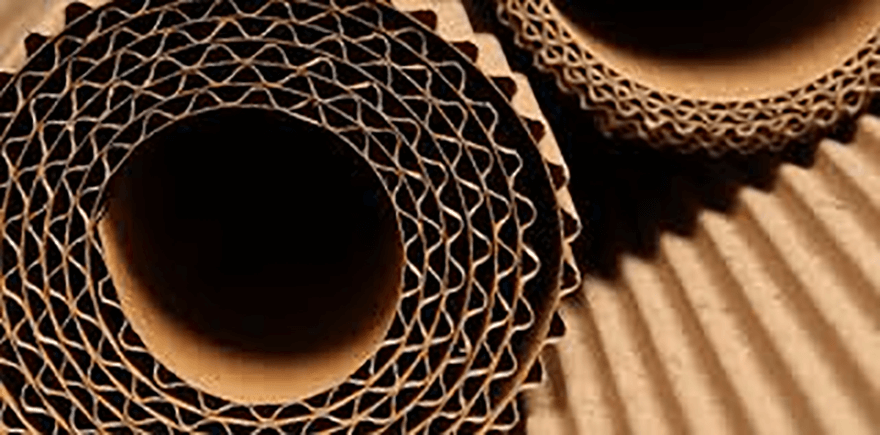

Choose environmentally friendly materials. In response to the call of the green theme of the times, to reflect the concern and participation of manufacturers and cooperative brands in environmental protection, and to shorten the emotional distance with consumers, Jary always chooses to use environmental protection materials such as “corrugated paper” and other “recyclable cardboard” and “degradable materials”. Materials for production packaging.

How is corrugated paper environmentally friendly?

Renewable resources. Corrugated paper is made of wood pulp, which can be reused after floating sorting, bleaching, recycled paper manufacturing and other processes;

Biodegradable: Corrugated paper is a degradable material, which means that it can be degraded naturally without taking too long in the natural environment. damage to the area;

Light weight: Corrugated paper is light in weight, and does not need to consume a lot of fuel during transportation, which helps to reduce greenhouse gas emissions;

Energy saving: Corrugated paper is different from plastic or metal substances, and requires a lot of energy in production. Using corrugated paper as packaging materials can reduce energy use and consumption in the production process;

Versatile use: Corrugated paper can be used in a variety of packaging applications, from shipping boxes to protective pads. This versatility means it can be used in many different industries.

Summarize

Packaging is a necessary tool that can speak for the brand and convey messages to consumers. Being serious about packaging is also a comprehensive grasp of the overall quality of the product. JERL has insisted on customizing the most suitable packaging products for customers since 2010. If you want to put on a “new dress” that fits the product, you are welcome to contact us, and we will provide you with the best quality and comprehensive services.

Hua Xu has been working hard on the road of custom packaging. Next time when you feel the need to impress someone with your brand, think of Hua Xu Packaging!