CUSTOMIZED CUBE BOXES

Currently, cube box packaging has become a powerful marketing tool. Well-designed packaging can create convenience value for consumers and promotional value for producers. A variety of factors will promote the further development of packaging as a marketing tool. As more and more products are sold in the form of self-service in supermarkets and discount stores. Now, cube box packaging has to perform many merchandising tasks. Packaging has many meanings.

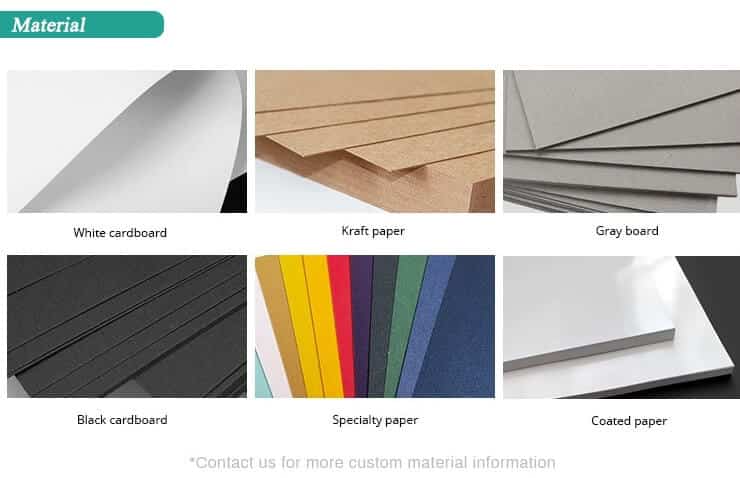

- Packaging Materials: Corrugated Paper, Kraft Paper, Ivory Paper, Specialty Paper, Cardboard.

- Size: Available in all shapes and sizes.

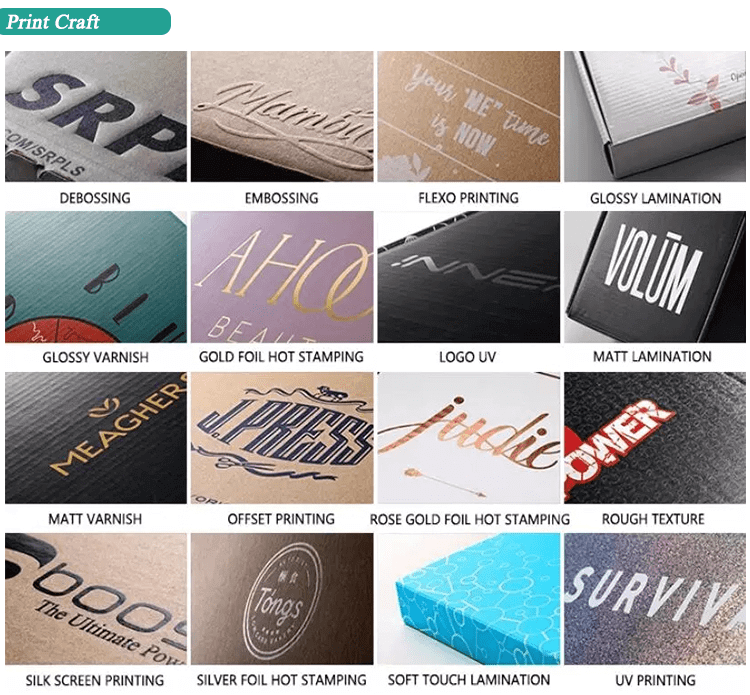

- Finishing options: Glossy, Matte, Aqueous Coating, Spot UV, Embossing, Debossing,

- Add on choices: Die cut window, gold foiling/silver foiling.

- Corrugated Cardboard, EVA Foam, Sponge Foam, EPE Foam, PVC, Silk Satin, Padded Pillow.

- Lead Time:1-3 working days for samples; 10 working days for mass production.

Q: How to process the order?

- Pls, send us the files you have, such as the logo AI file, and printing file.

- We will send you the template of the box after our designer finished it, and we will go ahead to do the pre-production sample after you confirmed the template.

- We will show you the video of the finished sample, after you confirmed the sample, we will start to do mass production.

- We will show you a video after the bulk order is ready, and then ship it out to you.

Q: How to protect the box without damage during shipping?

A: Each box will pack in a poly bag, 20pcs~30pcs pieces in a stronger carton box, and all the carton corners with plastic protectors.

Q: What’s the shipping option?

A: We can ship by UPS or DHL for small orders, and for bulk orders, we can ship by sea, DDP, DDU, and CIF services available.

Q: How can you guarantee your quality? If we don’t satisfy your quality, how will you do?

A: Normally we do samples for you to confirm everything, and production will be the same as samples, and each process with 100% inspection to control the quality

Q: How to protect the box without damage during shipping?

A: Each box will pack in a poly bag, 20pcs~30pcs pieces in a stronger carton box, and all the carton corners with plastic protectors.

Q: Is there any choice for the lining inside the box?

A: We can offer paper card lining, EVA lining, EPE lining, Sponge lining, satin lining, and blister lining, I can recommend suitable lining according to your product.

Q: What’s the logo craft?

A: We can do a hot stamping logo, UV logo, embossed logo, and debossed logo.

Q: What’s the lead time for bulk orders?

A: Normally our lead time is 5-12 working days.

Q: Do you have the Europe EPR tax number?

A: Yes, JERL has got a legal Europe tax number since 2022, including France Packaging EPR, Paper EPR, and Germany Packaging EPR.

Q: How to make a payment?

A: T/T, D/P, L/C, PAYPAL, Western Union, Online Transfer, Apple Pay, Google Pay, Afterpay/Clearpay, and others. For more options, please contact us.

BENEFITS OF CUSTOMIZED CUBE BOXES

Protect the product and facilitate storage and transportation.

The most basic function of product packaging is to protect the product and facilitate storage and transportation. Effective product packaging can protect products from moisture, heat, cold, volatilization, pollution, freshness, brittleness, and deformation. Therefore, when packaging products, pay attention to the selection of product packaging materials and the technical control of packaging.

The cube box packaging can attract attention, describe the characteristics of the product, give consumers confidence and form a favorable overall impression.

Growing consumer affluence means consumers are willing to pay more for the convenience, looks, reliability, and prestige that good packaging brings. Companies and brand image companies have realized the huge role of well-designed packaging, which helps consumers identify which company or which brand is at a glance. Every film buyer immediately recognizes the familiar yellow-packaged “Kodak” film.

Packaging also offers opportunities for innovation.

Packaging innovations can bring huge benefits to consumers and profits to producers. In 1899, the Unida Biscuit Company innovated a package with a preservation device (cardboard, inner paper wrap, outer paper wrap) that gave cookies a longer shelf life than biscuit boxes, biscuit boxes, and biscuit tubs. Kraft Foods developed the canned cheese blend, which extended the cheese’s shelf life and earned the company a “reliable” reputation. Currently, the company is experimenting with sterilization pouches, which are containers made from metal mixed with plastic and are an alternative to cans. Some companies first put soft drinks in zip-top cans or liquid sprays in push-button cans to attract many new customers. Now, winemakers are experimenting with packagings such as pull-top cans and carton bags.

WHAT IS THE FUNCTION OF THE CUBE BOX PACKAGING?

First of all, we need to know what is a cube boxes.

In geometry, a cube is a three-dimensional solid object bounded by six square faces, facets, or sides, with three junctions at each vertex.

The cube is the only regular hexahedron and is one of the five Platonic solids.

A cube is also a square parallelepiped, an equilateral cuboid, and a rhombohedron. It is a three-sided square prism and a four-sided triangular trapezoid.

The cube is the dual of the octahedron. It has cubic or octahedral symmetry.

A cube is the only convex polyhedron whose faces are all squares.

A cube has eleven nets: that is, there are eleven ways to flatten a hollow cube by cutting seven edges. To color a cube so that two adjacent faces do not have the same color, you need at least three colors.

A cube is the only regularly tiled unit in three-dimensional Euclidean space. It is also unique among Platonic solids because its faces have an even number of sides, and thus, it is the only member of the group that is a zonohedron (each face has point symmetry).

A cube can be cut into six identical square pyramids. If these square pyramids are then connected to the faces of a second cube, you get a rhombic dodecahedron (combining pairs of coplanar triangles into rhombic faces).

For boxes, Cube Boxes are an inexpensive and cost-effective solution to meet your many packaging requirements. These boxes can be customized with many variations. They can be used in the packaging of retail goods as well as in gift-giving.

WHAT ARE THE STRUCTURAL TYPES AND TYPES OF CUBE BOXES?

Among all kinds of packaging, the cube box is a kind of packaging container with strong adaptability, and the cube box material, as a renewable material, has the best prospect of use. cube boxes are made of cardboard folded or pasted. There are many forms. According to their structural characteristics, they can be divided into the following two categories.

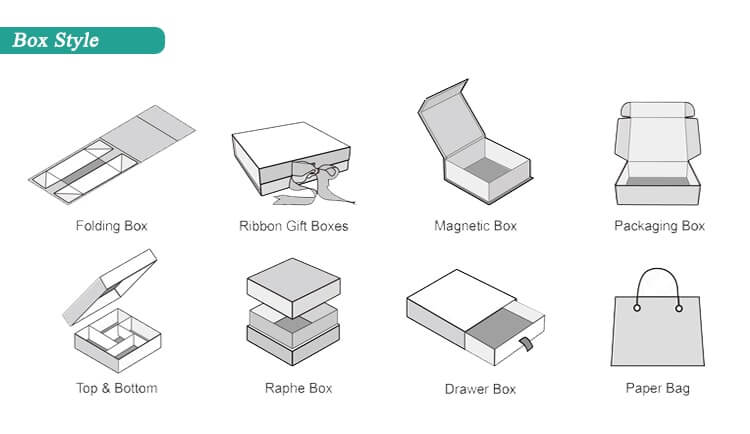

Folding cube boxes

Folding three-dimensional packaging boxes are folded into boxes with thinner cardboard, also known as thin-board three-dimensional packaging boxes. There are mainly the following structural types.

Two-page folding cube boxes

It consists of two parts: the bottom of the box and the cover of the box. The empty box can be flattened and fixed with tongues at both ends. After the carton is covered, the four walls become double-layer cardboard, which has higher strength than the single-layer folding box. In addition to the above-mentioned styles, there are many kinds of folding carton structures, such as window opening, plug-in type, drawer type, lining type, sleeve type, regular polyhedron type, scalene type, etc.

Cut lid folding cube boxes

It is made of a piece of cardboard, and the two ends of the box are overlapped and interspersed with insert ears to make it fixed. The box body is shallow and the opening is large. The entire carton does not need to be glued. Suitable for packaging toys, medicines, handicrafts, etc.

Portable folding cube boxes

After the box is formed, the bottom is firmly glued and can be bent and folded. The box blank is attached with a flap, which can be fastened and easy to carry. It can pack alcohol, bottled medicine, etc.

Adhesive folding cube boxes

After the side of the box is folded, the seams need to be glued to form a box. Such boxes can be crushed for transportation, but cannot be fully unfolded. It is often used in the packaging of stationery and bottled medicines.

Fixed cube boxes

The shape of the fixed three-dimensional packaging box is fixed and cannot be folded. It is mostly made of thicker cardboard by pasting or stapling. Since it cannot be folded, it takes up a lot of space during storage and transportation and is easily damaged. According to its structure, it can be divided into 6 types

Sleeve cover cube boxes

The heights of the bottom and the cover are equal, and they are assembled so that the assembly is stable and rigid.

Cylinder covers cube boxes

The height is large, the diameter is small, and it is cylindrical. The cross-section of the cylinder is mostly circular, but it can also be a regular polygon. The cover is shallow, such as a typing wax paper box.

Shake the lid of the cube boxes

Its cover can be swung open and closed on an axis, such as an injection box.

Drawer cube boxes

It is like a drawer-type opening and closing, such as a matchbox and a staple box. Some drawers also have flexible handles.

Cube boxes with an open window

A window is opened on the front of the box to display the contents, and it can also be hung for display.

Special-shaped cube boxes

The box itself is shaped like a heart, an ellipse, a star, etc., or the top is a curved surface. Heart-shaped box, its shape is novel and unique.

WHAT ARE THE MAIN RAW MATERIALS OF THE CUBE BOXES?

In the whole process of packaging design development, paper packaging materials, as a common packaging material, are widely used in production and life practice. The paper is low in cost, suitable for mass mechanized production, has good formability and folding properties, suitable for fine printing, and has the advantages of recyclability, economy, and environmental protection.

Kraft paper

Kraft paper is inexpensive, with nice folding resistance and water resistance. Most of it was used to make shopping bags, envelopes, cement bags, and so on.

White cardboard

Whiteboard paper is hard and thick, with good standing strength, surface strength, folding resistance, and printing adaptability, and is suitable for packaging boxes, linings, etc.

Coated paper

Coated paper is mainly refined from high-grade raw materials such as wood and cotton fibers, and is divided into two types: single copper and double copper. It is suitable for multi-color overprint printing, with bright colors and rich layer changes after printing. Commonly used in the production of handbags, business cards, and books, magazine covers.

Corrugated paper

The corrugated paper has the advantages of lightness and sturdiness, strong load and pressure resistance, shock resistance, moisture resistance, etc., and the cost is low. Single-sided corrugated cardboard is generally used as a lining protective layer for commodity packaging or to make lightweight cardboards and pads to protect commodities from vibration or impact during storage and transportation; three-layer or five-layer corrugated cardboard is used to make commodities for sale. Packaging; seven-layer or eleven-layer corrugated cardboard is mainly used to make packaging boxes for mechanical and electrical products, furniture, motorcycles, and large household appliances.

Generally, in the process of customer requests, the customer can choose the material of the cube box.

WHAT IS THE SURFACE TREATMENT OF THE CUBE BOX?

Surface processing is to improve the appearance and quality of the packaging, mainly including lamination, and the main processes are concave and convex embossing, die-cutting indentation, and other processing technologies.

Lamination

The lamination is a transparent plastic film that is hot-pressed to the surface of the cube box, which is flatter and brighter, and the color of the pictures and texts is more obvious. At the same time, it also has the effect of being waterproof and anti-fouling. Hot stamping, glazing, and waxing are surface processing techniques; film coating can make the cube box surface wear-resistant, folding-resistant, and chemical-resistant. However, because the plastic film is not degradable, it is difficult to recycle and easily causes pollution. Therefore, the plastic lamination process should be used with caution.

Freezing Snowflakes

The freezing point snowflake effect is a kind of fine sand and hand feeling formed on the surface of the cube box after ink silk screen printing on the cube box such as gold cardboard, silver cardboard, laser cardboard, PVC, etc. after being wrinkled by UV light and cured by UV light. Subtle effect. The surface of the cube box presents an effect like a layer of thin snow or ice, commonly known in the industry as “snowflakes” (larger patterns) or “freezing points” (smaller patterns). This process has the characteristics of fine pattern, strong three-dimensional effect, luxurious and elegant visual, and is widely used in tobacco and wine boxes, calendars, gift box packaging or other exquisite cube boxes.

Polish and wax

Glazing is to coat or spray a layer of colorless transparent paint on the surface of the cube box, brush the gloss of the product, and waterproof and oil-proof on the surface of the cube box. The item has a bright luster and plays a nice barrier effect. To make a glossy film to increase the printing wax is to apply hot melted wax to the wrapping paper.

Embossed embossing

Concave-convex imprinting is to use a concave-convex mold to plastically deform the cube box substrate under certain pressure and then process the surface of the cube box. The embossed convex graphics and patterns show different shades of patterns, with an obvious sense of relief, which increases the cube box sense and artistic appeal of the printed matter.

Partial UV process

It is a screen printing process that enhances the colorful effect of the cube box by partially coating the surface of the cube box with UV varnish.

Die-cut indentation

Die-cutting and indentation are when the cube box needs to be cut into a certain shape, it can be done through the die-cutting and indentation process. Die-cutting is a die-cutting process of arranging steel blades into molds, frames, etc.

Photolithographic paper

A cube box paper material with very high technical content, which integrates advanced technologies such as local embossing, holographic laser anti-counterfeiting, vacuum aluminum plating, paper-plastic composite slitting, and nesting printing, which has changed the previous situation of single laser pattern effect. The dazzling visual effect is unique, and it has a unique anti-counterfeiting function, which not only prevents copying and plagiarism, but also facilitates consumers to intuitively identify authenticity.

Bronzing

Hot stamping is divided into hot gold, silver, laser gold, bronze gold, etc. Generally, hot stamping or silver is only after the glue has passed; the film must have an alignment line; but according to the base material of hot stamping, it is also classified into hot stamping paper and hot stamping. Flannel hot plastic and so on.

Hot stamping

Hot stamping is to print various aluminum foils on the cube box with the help of certain pressure and temperature, showing a strong metallic light, making the product have a high-grade texture. At the same time, due to the excellent physical and chemical properties of aluminum foil, it can protect the cube box. Therefore, the hot stamping process is widely used in cube boxes printing.

Reverse scrub

The reverse frosting process is a new type of printing process that has appeared in the past one or two years. It needs to be processed through several special primers or varnishes to complete; it is regarded as a new process of partial glazing. The process is to print the cube box according to the normal color sequence, after the ink is completely dried or cured, a layer of special primer is printed on the local area that does not need to highlight high brightness by offset printing connection (or offline). After the primer is completely dry, apply UV varnish on the entire surface of the cube box in a full-plate manner. In this way, a cohesive reaction occurs in the contact area between the UV varnish and the primer to form a small granular ink film, which constitutes a matte or frosted matte surface; and a high-gloss mirror surface is formed in the UV varnish area where the primer is not printed. Eventually, the cube box surface forms local high gloss and local matte low gloss areas. Two completely different gloss effects achieve a high-contrast effect of partial images, embellishing and accentuating graphics with a glossy mirror finish.

Embossed bronzing

This process is a hot stamping method with a stronger metallic and three-dimensional sense through the change of the hot stamping version. Through the concave and convex changes of the relief pattern, the cube box presents a metal relief-like texture, which makes the bronzing graphics jump out of the plane and brings a stronger visual impact.

Laser Transfer

It has dazzling visual effects, which can effectively improve the quality of packaging. This process can print full or partial transparent laser effects on the cube box with smooth surface, which has changed the previous only using laser paper for printing, or in the cube box. The box is compounded with a proprietary laser film to show the processing method of the laser effect, which can make the laser pattern flexible and changeable.

Embossed bronzing

This process is a hot stamping method with a stronger metallic and three-dimensional sense through the change of the hot stamping version. Through the concave and convex changes of the relief pattern, the cube box presents a metal relief-like texture, which makes the bronzing graphics jump out of the plane and brings a stronger visual impact.

Laser Transfer

It has dazzling visual effects, which can effectively improve the quality of packaging. This process can print full or partial transparent laser effects on the cube box with smooth surface, which has changed the previous only using laser paper for printing, or in the cube box. The box is compounded with a proprietary laser film to show the processing method of the laser effect, which can make the laser pattern flexible and changeable.

ABOUT HOW TO CUSTOMIZE THE CUBE BOXES?

First, You (customer) provide us with your product. For your product, we have a professional design and structure team to design a customized packaging box to your satisfaction.

Second, If you have a packaging box suitable for your product, you can take a picture or send the box to our packaging box manufacturer, then we will design the cube box according to the one you provide.

Third, Provide specific ordering requirements cube box size + paper quality and thickness (or other materials) + style + printing method + printing process + customized quantity + additional processes, etc., we can accurately quote you. (The customized quantity is very important, the more quantity, the lower the price, because it involves issues such as version fee Q, start-up fee, loss, etc.), then we can provide you an advice and guidance on the process!

Product size, length x width x height

Determine the material, leather, cloth outer packaging, cardboard + special paper/double copper paper/single powder card

Determine the style of the packaging box. Drawer box, heaven and earth cover box, flip box, special-shaped box, personality box

Determine the accessories of the box. Such as handbags, inner trays, inner bags, transport boxes

Determine the printing method + technological process, embossing + silk screen printing / partial UV / embossing / hot stamping / hot silver

Proofing. Due to the particularity of the packaging, the customer has no intuitive concept of the appearance of the packaging box. We can design the renderings or make a sample for you, and then send it to you, waiting for your confirmation. In addition, if you bring your design draft, you need to send us your manuscript files

Confirm the order. After confirming that the sample (packing box) is correct, you can place an order for us, and the company will start the customized production of the packing box

Payment/Invoicing. Payment by bank card or cash when placing an order, down payment of 30% deposit, the balance must be paid before delivery. (Invoices need to add tax points)

Confirm receipt. When you choose JERL, you choose a friend and an opportunity!

A cube box has many advantages, but an unqualified cube box cannot reflect these benefits and values, so we must pay attention to avoid choosing those boxes with poor workmanship and no features when choosing a cube box. If you need to customize the cube box, you need to communicate with the manufacturer in advance to discuss the design, pattern, material, and appearance quality of the cube box. Of course, you can also take the cube box sample for testing, and finally confirm whether it meets your requirements. For the Custom Cube Box, JERL packaging is a very good choice, this is our suggestions.

If you don’t know which material suitable for your product, you can contact us, we will give you some professional advice according to your product .

Hua Xu has been working hard on the road of custom packaging. Next time when you feel the need to impress someone with your brand, think of Hua Xu Packaging!